Injection Molding

Caps and Closures

Other Products

Ranging from 2 - 144 cavities

Injection Stretch Blow Molding

Jars and Containers

PET / PP / PC / PETG / TRITAN

Ranging from 2 - 24 cavities

Extrusion Blow Molding

Bottles

Jars and Containers

Ranging from 1 - 18 cavities

Injection Blow Molding

Bottles

Jars and Containers

Ranging from 2 -12 cavities

ONE STEP AHEAD

The regular practice of improvements based on data and evaluations in all areas of operation with significant emphasis on the active involvement of customers, suppliers, and employees, along with adherence to documented procedures and constant up-gradation of technology, ensures that Chemco's customers remain one step ahead of their competition at all times.

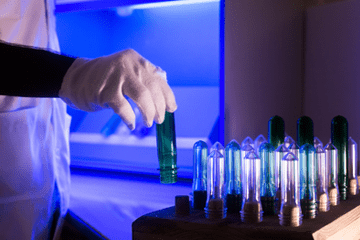

RESEARCH AND DEVELOPMENT

Research and Development are carried throughout all functions and operations. They are not only limited to launching and manufacturing new products. With over 20 R&D dedicated staff members, Chemco has the quickest adoption periods in the industry. Many established and proven innovations of the company are visible in everyday life and used by millions.

STRINGENT TESTING AND VALIDATION

Every product manufactured at Chemco's manufacturing facilities undergoes stringent testing and validation before being introduced and included in our product range. We enlist the help of various top-rated third-party organizations for checking and re-checking our promise to our customers. This is one of the key reasons that the company remains the preferred choice amongst other alternatives.