Chemco has expanded its expertise over the past six years to specialize in the manufacturing and export of high-quality woven coated fabrics. Today, customers around the world trust Chemco for our commitment to excellence, reliable delivery, and consistent exceptional quality and service.

The lumber industry continues to face supply challenges for Lumber Wraps. Many suppliers lack fully integrated manufacturing, resulting in limited visibility and control throughout production. As a result, inconsistencies in quality and delivery can arise, ultimately affecting overall supply chain reliability.

At Chemco, we bring every step of the manufacturing process under one roof, ensuring total control, traceability, and reliability. Our integrated facility includes:

This end-to-end capability sets Chemco apart, giving you the confidence that every roll/bag of our lumber wraps will meet the highest standards delivered on time, consistently.

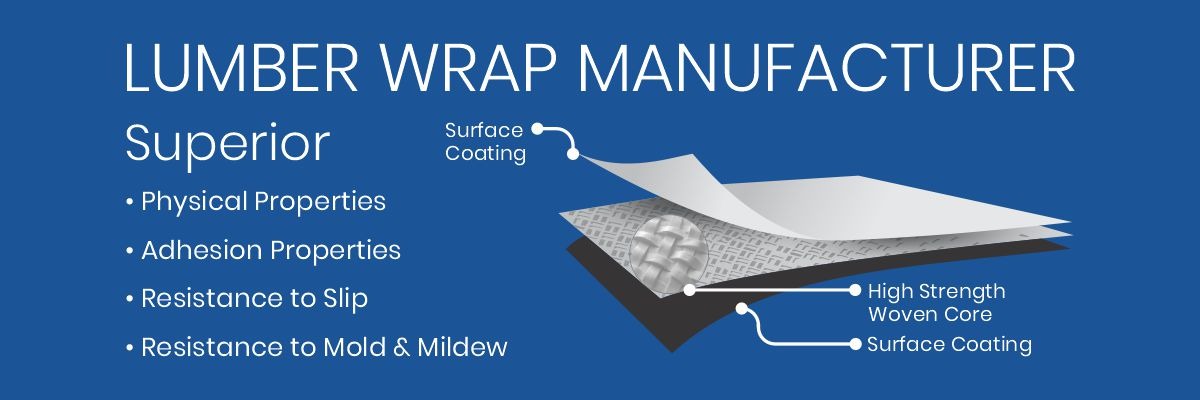

This ultimate wrapping solution engineered by Chemco is designed to safeguard your products from air, moisture, mold, mildew and dust. Chemco’s lumber wraps combines durability, flexibility, and sustainability to deliver unmatched performance in every climate. Made from 100% virgin Polypropylene (PP) / Polyethylene (PE) resins, our wraps are soft, durable, and easy to handle, helping you pack efficiently either manually or on an automatic Do2 machine while maintaining a premium look.

Manufactured at our state-of-the-art facility, Chemco’s lumber wraps feature a proprietary weave that delivers exceptional tensile and tear strength, ensuring your products stay protected through storage, handling, and transport. Whether exposed to sunlight, rain, or dust, Chemco’s lumber wraps stand strong. Its UV-stabilized formulation protects your product for well over a year in outdoor conditions, maintaining its integrity and appearance. We believe in protecting your products and the planet. Chemco’s lumber wraps are fully recyclable, and aligning perfectly with the Go-Green initiative and supporting sustainable business practices.

Lumber wrap applications for covering include but are not limited to the following types of wood:

Southern pine (SPF), Cross Laminated Timber (CLT), Engineered Wood Products (EWP), Oriented Standard Boards (OSB), Fire Retardant Treated Wood (FRTW), Fullpac/Halfpac stacks, Timber posts beams & joist, Kiln-Dried wood, re-manufactured lumber, MDF/particle board, Post Frame Solution, Window/Door decking panels

COLD CRACKING RESISTANT

UV RESISTANT

SLIP RESISTANT

INERT TO MILDEW & MOLD

STAPLE-STRIP ZONE

| Description/ Test Name |

Orientation | Test Method |

Unit of Measure |

Lumber Wrap 75 |

Lumber Wrap 85 |

Lumber Wrap 95 |

Lumber Wrap 100 |

Lumber Wrap 125 |

|---|---|---|---|---|---|---|---|---|

| Typical Values¹ |

Typical Values¹ |

Typical Values¹ |

Typical Values¹ |

Typical Values¹ |

||||

| Raw Material | -- | -- | -- | PP | PP | PP | PP | PP |

| Thickness | -- | ASTM D751 |

mil | 3.4 ±10% | 3.9 ±10% | 4.1 ±10% | 4.5 ±10% | 6.0 ±10% |

| Finished Weight |

-- | ASTM D5261 |

g/m² | 75 ± 5% | 85 ± 5% | 95 ± 5% | 100 ± 5% | 120 ± 5% |

| Nominal Weave |

MD X CD | ASTM D3775 |

ppi | 5 X 5 | 5 X 5 | 5 X 5 | 10 X 5 | 10 X 5 |

| Product Width | CD | ASTM D3774 |

inches | Up to 144 |

Up to 144 |

Up to 144 |

Up to 144 |

Up to 144 |

| Colour | -- | -- | Visual | White / Black & Beige / White |

White / Black & Beige / White |

White / Black & Beige / White |

White / Black & Beige / White |

White / Black & Beige / White |

| 2" Strip Tensile Strength |

MD | ASTM D5035 |

lb | 85 | 100 | 110 | 170 | 200 |

| CD | ASTM D5035 |

lb | 75 | 95 | 100 | 120 | 130 | |

| Elongation at Break (%) |

MD | ASTM D5035 |

% | 20±5 | 20±5 | 20±5 | 20±5 | 20±5 |

| CD | ASTM D5035 |

% | 20±5 | 20±5 | 20±5 | 20±5 | 20±5 | |

| Breaking Strength (By Grab Method) |

MD | ASTM D751 |

lb | 70 | 75 | 85 | 140 | 150 |

| CD | ASTM D751 |

lb | 65 | 70 | 80 | 95 | 105 | |

| Trapezoidal Tear |

MD | ASTM D4533 |

lb | 18 | 25 | 28 | 35 | 45 |

| CD | ASTM D4533 |

lb | 15 | 22 | 25 | 30 | 35 | |

| Bursting Strength |

-- | ASTM D751 |

psi | 110 | 140 | 140 | 160 | 180 |

| Accelerated UV Weathering (500 hours Exposure @ 0.89 W/m²/nm) |

-- | ASTM G154 |

% | >80% | >80% | >80% | >80% | >80% |